Structural Ipe Wood Tiles

Shipping cost (including for samples) calculated at checkout

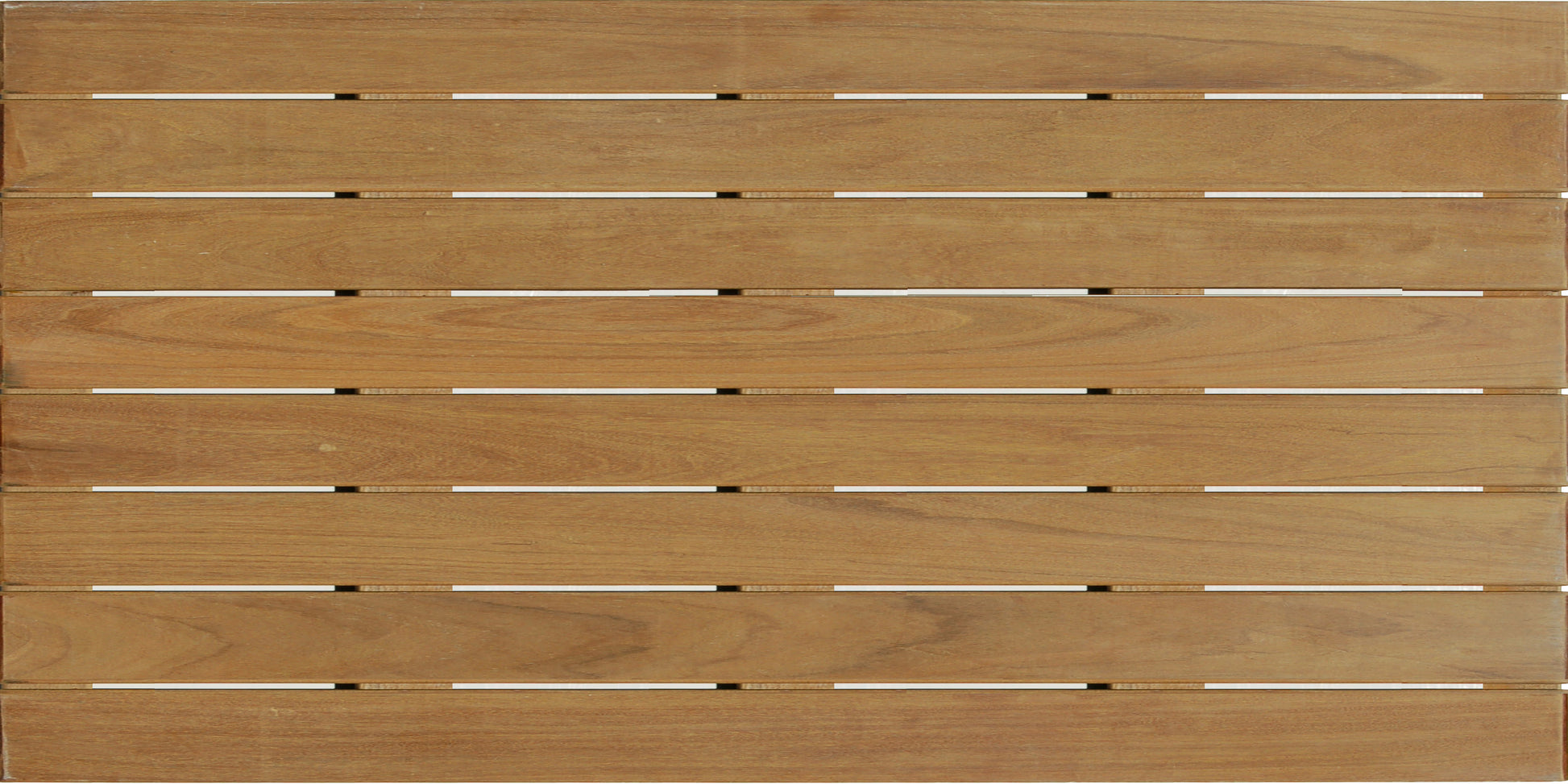

Structural Ipe Wood Tiles

Archatrak Ipe wood structural tiles mounted on adjustable height pedestals create highly stable, long-lasting and aesthetically pleasing elevated decks for both commercial and residential applications.

Unlike traditional wood decks with planks that need to be individually laid and secured to wood joists supported by a wood or steel sub-structure, Archatrak structural Ipe decking tiles are supported only with adjustable height pedestals placed under each corner of the tiles. This enables much faster installation and reduced labor costs.

| Standard tile sizes | 23 7/16” x 23 7/16”, 23 7/8″ x 23 7/8″ or 23 7/16″ x 47" |

|---|---|

| Tile weight | 6 lb/sq.ft approx. |

| Tile height | 1 11/16″ |

| Wood thickness | 13/16″ |

| Slats per tile | 8 |

| Width of slats | 2 7/8″ |

| Slat spacing | 3/16″ approx. |

| Ends & sides finish | S4S E4E (radius 1/8″) |

| End treatment | waxed with paraffin |

| Surface finish | not coated with oil |

| Fixing screws | stainless steel |

| SRI (new) | 41 |

| SRI (weathered) | 24 |

| Slip resistance (ASTM E303-22) | Dry: 67 Wet: 28 |

| Fire rating (ASTM E108 Spread of flame) | Class A |

| Fire rating (ASTM E108 Intermittent flame exposure) | Class A |

| Botanical name | Tabebuia sp. |

|---|---|

| Color | Reddish brown, but can vary from olive brown to blackish |

| Grain | Interlocked grain, fine to medium texture |

| Density | 64 lb/ft3 |

| Durability | Class 1 (min. 25 years life) |

| Hardness (Janka) | 3680 (very hard) |

| Decay resistance | 1 (very resistant) |

| Fire resistance (ASTM E84‐16) | Class B |

| Flame spread index | 35 |

| Modulus of rupture | 22,600 psi |

| Modulus of elasticity | 21,600 MPa |

| Crushing strength | 13,000 lbf/in2 |

| Shrinkage | 7% tangential, 6% radial |

| Tang./radial shrinkage | 1.2 |

| Standard tile sizes | 23 7/8″ x 23 7/8″ or 23 7/8″ x 48" |

|---|---|

| Tile weight | 6 lb/sq.ft approx. |

| Tile height | 1 11/16″ |

| Wood thickness | 13/16″ |

| Slats per tile | 8 |

| Width of slats | 2 7/8″ |

| Slat spacing | 3/16″ approx. |

| Ends & sides finish | S4S E4E (radius 1/8″) |

| End treatment | waxed with paraffin |

| Surface finish | not coated with oil |

| Fixing screws | stainless steel |

| SRI (new) | 41 |

| SRI (weathered) | 24 |

| Slip resistance (ASTM E303-22) | Dry: 67 Wet: 28 |

| Fire rating (ASTM E108 Spread of flame) | Class A |

| Fire rating (ASTM E108 Intermittent flame exposure) | Class A |

- High resistance to termites, decay and mold

- One of the hardest timber species available

- Wear resistant and scuff resistant

- Class A fire rating

- High bending and shearing strength

- High resistance to warping and twisting

- Weathers without splintering

- Good resistance to staining

- Lower maintenance than other wood species

- High resistance to mold & mildew

Advantages of Archatrak Wood Decking Tiles for Rooftop Decks

Archatrak structural Ipe wood decking tiles supported by adjustable height pedestals can be used to build attractive, highly stable, and durable elevated decks for both commercial and residential applications.

While decks with natural Ipe planks supported by wood or steel joists are still very commonly used for wood decks on rooftops, Archatrak Ipe wood structural tiles mounted on adjustable height pedestals nevertheless offer a number of distinct advantages.

Unlike traditional wood planks that need to be individually secured on a wood or steel support structure, Archatrak structural Ipe tile decking requires no additional support other than the pedestal supports.

If installing a deck on an existing rooftop, the tiles and the support pedestals can often be transported in a goods elevator – no cranes or heavy lifting equipment required.

Since 24" x 24" Ipe wood decking tiles weigh only 23lb approx., an Archatrak structural wood tile deck puts much less additional weight on a rooftop than a conventional Ipe plank deck on wood or steel joists.

Pedestals are simply placed over the roof membrane, typically at 24″ spacing, their wide base spreading the load and avoiding damage to any membranes.

Archatrak Ipe tiles are equally as attarctive as traditional decking, with clean lines and consistent appearance. The laying pattern gives a clean, professional look that can enhance the overall look of the rooftop.

No screws or nails are required for installation, and all screws used in making the tiles are only visible from the underside.

Archatrak structural wood tiles can be easily cut to fit around rooftop structures and can be integrated with other materials such as porcelain pavers and green roof trays.

Should any tile become damaged or stainied, you can easily lift up the damaged tile and replace it with a new one.

Advantages of Using a Pedestal System to Build a Wood Deck

Advantages of Using a Pedestal System to Build a Wood Deck

Pedestals can be easily adjusted to ensure a perfectly level deck, irrespective of the slope of the roof.

The gap under the tiles permits water to flow away freely, preventing water from pooling underneath the deck.

Since individual tiles can be simply lifted up, it is easy to inspect and perform any maintenance on the roof membrane.

Archatrak Ipe Tile Installation Guidelines

Archatrak structural Ipe wood pavers only need to be supported at each corner with our ‘Prime’ adjustable height deck supports.

Where clearance under the tiles is less than 1 1/2″, the tiles can be supported with our fixed height rubber support pads which will raise the tiles off the surface so water can drain away freely.

Precautions for Windy Locations

Since Archatrak Ipe wood tiles are relatively light compared to wood planks, a hold down assembly can be installed to lock the tiles in a fixed array. A washer is inserted in a precut slot in each corner of the tiles and a stainless-steel screw inserted through the washer into the head of pedestals, securing the corners of the tiles tightly to each pedestal. Ask us for details.

Our Commitment to Sustainable Forestry Practices

Our standard structural Ipe wood decking tiles are constructed from responsibly harvested Forest Stewardship Council® Certified Ipe wood (FSC® C113128). FSC certification assures wood products are backed by a reputable system of verification. Non FSC Ipe wood tiles and special size Ipe wood tiles can be supplied on request, subject to minimum order sizes and lead times.

Archatrak Ipe wood decking tiles are manufactured using ‘A’ grade lumber which, in accordance with standard industry classification, permits some knots, color variation, dark streaks, pin holes, checking etc. Decking timber is not furniture grade.

Archatrak Ipe wood decking tiles are supplied in a natural, unfinished state. It is highly recommended that a good quality decking oil is applied as soon as practical after installation, which assists in maintaining the color as long as possible, and providing some protection from airborne particles which may leave dark marks on unfinished tiles.

In accordance with normal industry practice, our Ipe wood decking tiles are treated with wax on the ends of the wood slats to reduce the possibility of end cracking. During handling and transport, some wax might be deposited on the surface of the slats.

Be aware that this wax may sometimes ‘bleed’ a short distance along the top surface of the slats after installation, especially when the tiles are exposed to hot, sunny conditions and when the tiles have not been coated with a good quality decking oil after installation. This can often look like the ends of the slats have been saturated with water.

Although this should disappear over time, we nevertheless strongly recommend applying a good quality decking oil to the wood tiles as soon as practical after installation to reduce the potential for ‘bleeding’ and reduce the rate of color fading.

Even when some weathering has occurred, some wax can remain in the pores of dry wood, which may be visible as a difference in color between the wax coated tile ends and middle of the slats when the tiles are wet.

Archatrak Ipe wood tiles are specifically designed for installation using adjustable height pedestals on each corner of the tiles.

Fixed height rubber pads can also be used for patio resurfacing, but good air circulation must be maintained under the tiles and the tiles must not be subject to prolonged contact with water.

Our hardwood decking tiles are not factory coated with any decking oil but are supplied in a natural unfinished state. A good quality decking oil should be applied as soon as practical after installation

Repeat coating with a sealer or decking oil at regular intervals is recommended to preserve the appearance of the tiles.

Archatrak Inc. warrants to the original purchaser that its structural Ipe wood pavers shall be free from material defects in workmanship and materials for a period of three (3) years from the date of original purchase, under normal use and service condition.

Defects are defined as imperfections that impair the utility of the product for its normally accepted purpose.

Archatrak donates a portion of the proceeds from each Ipe wood paver sold, through our partnership with Trees for the Future. This donation facilitates the planting of 2 trees for every wood paver sold.

Trees for the Future (TREES) is an international development nonprofit that meets a triple bottom line by planting trees: poverty alleviation, hunger eradication, and healing the environment. Working across 6 Sub-Sahara African countries TREES has planted over 150 million trees since 1989.